Don’t want plaster that falls apart? Selecting the right plastering materials is crucial if you want a

smooth finish that lasts.

Wrong materials mean cracks, peeling paint and wasted money on redoing the job. It’s one of the most common homeowner errors.

So…

Let’s help you avoid that problem. We’ll show you what to consider when selecting plastering materials. The best way to prevent plaster problems is at the start. By spending a little time choosing right first, you avoid a lot of hassle later.

What you’ll learn:

- The Importance of Plastering Materials

- Overview of Plaster Types

- Choosing Plastering Materials

- Durable Materials for Different Rooms

- Common Mistakes in Plaster Material Selection

The Importance of Plastering Materials

Drywall or plaster isn’t just cosmetic. It protects brickwork, insulates your home and in some cases can improve fire resistance. But all these benefits require the correct plastering materials.

What happens when they’re not correct:

- Cracks form within months

- Damp patches and mould develop

- Paint can’t adhere and starts to peel

- The entire job has to be redone

As UK homeowners continue to renovate (51% did so in 2024), plastering materials matter more than ever before. The UK plastering industry is now worth £3.3bn in 2025. That’s a lot of choice. With that level of competition, you could be forgiven for thinking that any plaster is just as good as the next.

Far from it.

Most problems are down to using the wrong materials or methods for the job.

For instance, many home improvement projects now involve plastering walls, ceilings or both. Whether it’s using skim coat plaster to redo a ceiling or plastering over tiles for a new look, getting the materials wrong leads to failure. Floors can crack, ceilings sag and the job looks awful. If the plastering material isn’t suited to the environment, then failure is inevitable.

Does it make sense?

Selecting the right plastering materials when you need a ceiling plastered or walls refinished is just the first step. Understanding your options helps you ask the right questions. It also helps you spot when something isn’t right.

Not a bad return on a few minutes reading.

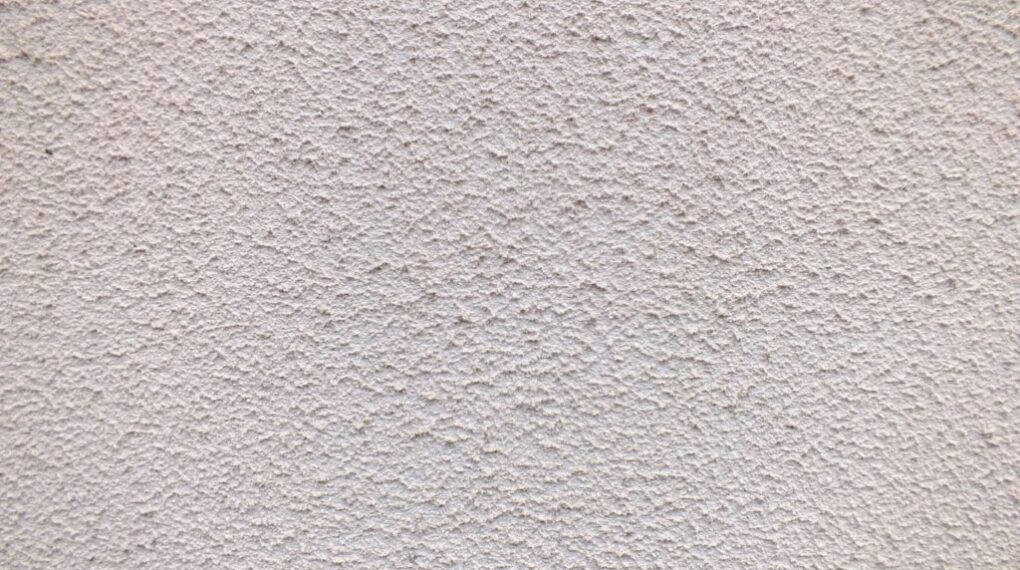

Overview of Plaster Types

Different plasters have different strengths.

They also have varying weaknesses. We can summarise most materials as falling into one of three categories. Before we do that, remember there are tons of proprietary products too.

Trade names for plaster come and go. Here we focus on the main materials. This helps avoid getting bogged down in the constant barrage of marketing messages plasterers receive. They tell them “X product is the best”. It’s more effective to home in on what makes a product better.

Okay, onto those three main types…

Gypsum Plaster

Interior gypsum plaster 90% of the time sets relatively quickly. Provides a super-smooth finish that’s easy to paint or wallpaper. Gypsum is fire-resistant. It also provides decent soundproofing insulation.

It can’t cope with moisture though. Bathrooms and kitchens require adequate ventilation to use it. Or more precisely, not to make a massive mistake.

Cement Plaster

The workhorse of exterior plastering. Withstands wet conditions incredibly well. A popular choice for external rendering. Cement plaster is waterproof by design.

It’s highly durable and can handle extreme weather. Cement plaster use is rising as a result.

Pros:

- Excellent water resistance

- Withstands tough outdoor conditions

- Very durable and hardwearing

Cons are it’s not easy to work with. Smooth, paintable surfaces are hard to achieve without experience.

Lime Plaster

Been around for centuries. A traditional plaster used in period properties. Lime plaster “breathes”.

For old buildings, this is important. Bricks, mortar and plaster need a way to release trapped moisture. Lime provides it.

It’s also flexible. A little more than modern plasters. Walls and ceilings flex as the building settles. Lime can cope with this movement without cracking.

Choosing Plastering Materials

It’s about matching the right plaster to the environment.

That means considering location and what it needs. A few questions to bear in mind when selecting plastering materials include:

Location? Interior or exterior?

Interior walls usually mean gypsum plaster. Exterior walls call for cement plaster, or a proprietary external product.

Moisture levels? High or low?

Kitchens and bathrooms are wet. Proper ventilation is needed if using gypsum in those areas. Moisture-resistant plasterboard or cement-based plasters work much better.

Dry rooms like living rooms? Gypsum plaster is fine.

Building age? Old or new?

Older properties benefit from lime plaster.

Durable Materials for Different Rooms

Each room in the house has different requirements:

Bathrooms and Kitchens

Hot, steamy areas. Normal gypsum plaster won’t last. Water-resistant plasterboard is a better bet. Cement-based plasters and specialist bathroom plaster are both good options too.

Upfront cost is higher. Pays for itself with longevity.

Hallways and High-Traffic Areas

Kids, pets, furniture etc. all batter walls in these rooms. Standard plaster can dent and scratch too easily.

Better to use a tough coat plaster or hardwall plaster in these areas. Designed to take the abuse that hands walls in these rooms.

Ceilings

Must be lightweight but tough. Set quickly so it doesn’t sag during application. Gypsum-based products typically perform best here. Old paint, grease etc. must be removed for proper adhesion.

Preparation makes the plastering materials work or not.

Common Mistakes in Plaster Material Selection

Three mistakes are the most common. Jumping straight in without the right materials is an issue. They must be suited to the application.

Jumping straight in without preparation is also a problem. Cracks and peeling appear when the surface wasn’t made ready first. Skipping prep steps is a very expensive mistake.

Mixing materials is a common error. Applying gypsum plaster over cement without preparation causes adhesion failures. Each plaster material has its own requirements. Using materials incorrectly won’t result in a successful job.

Cheap isn’t good value. Choosing a plastering material on price alone invites future problems. Budget plaster might look fine today. Cracks within six months and repair costs exceed initial savings by a wide margin.

Environmental conditions affect plastering success. Cold weather and damp surfaces cause problems. Temperature affects setting and curing times. Moisture prevents it from curing correctly.

Professional plasterers recognise unsuitable conditions. Waiting rather than plastering is preferable. Plastering jobs always look better when they can be done right the first time.

Conclusion

Selecting the right plastering materials isn’t hard when the basics are clear.

Match materials to the environment. Moisture levels, footfall and building type are the most important criteria. Don’t skimp on quality. Prepare the surface before plastering properly. Following these principles makes plaster problems far less common.

Let’s quickly recap:

- Gypsum for interior, dry areas

- Cement for exterior and wet conditions

- Lime for older properties that need breathability

The right plastering materials make a difference between plaster that lasts for decades or plaster that looks awful within months.

Get the materials decision right at the start, and your walls and ceilings will stay smooth and problem-free for a long time. Get it wrong and you’ll pay the price sooner than you’d like.